Which Software Is Better For 3D Printing Rhino Or Fusion 360?

The increasing popularity of 3D printing has led to a surge in the demand for software that enables the creation of 3D models. Rhino and Fusion 360 are two of the most widely used 3D modeling software programs in the industry. While both software programs have their unique features and capabilities, it is a common question among users to determine which one is better suited for 3D printing. In this blog, we will compare and contrast Rhino and Fusion 360 in terms of their features, ease of use, cost, and compatibility with 3D printing technology. We will explore the strengths and limitations of each software program and provide an objective analysis to help users decide which software is the better choice for their specific needs. Ultimately, the choice between Rhino and Fusion 360 will depend on the user’s preferences and requirements, and this blog will provide insights that will help users make an informed decision.

Features and Capabilities

Both Rhino and Fusion 360 offer a range of features and compatibilities that are essential for 3D printing, and each has its strengths in this area.

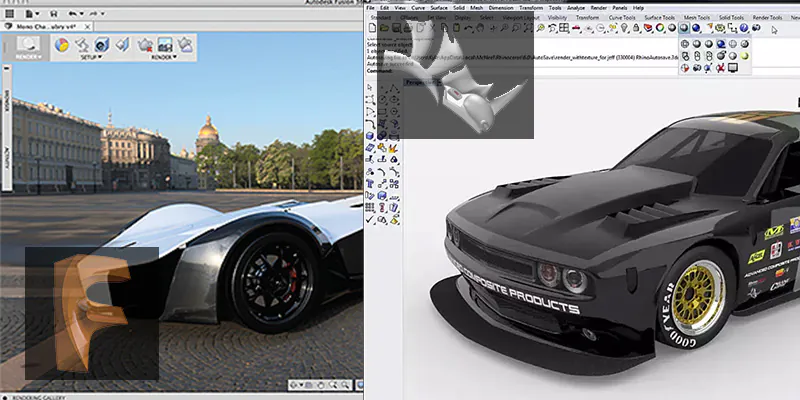

Rhino is well-suited for creating complex and organic shapes, making it a great choice for sculpting and creating models with freeform curves and surfaces. It offers a robust set of tools for mesh editing, surface modeling, and NURBS (Non-Uniform Rational B-Splines) modeling, allowing users to create highly detailed and precise models with ease. Rhino also supports a wide range of file formats, including STL, OBJ, and 3DM, making it easy to import and export files between different software tools and 3D printers.

Fusion 360, on the other hand, is a more comprehensive solution that includes not only 3D modeling but also CAM (Computer-Aided Manufacturing) and simulation capabilities. This makes it a great choice for users who need to create functional prototypes and parts for manufacturing. Fusion 360 also offers a range of advanced tools for generative design, simulation, and optimization, which can help users save time and improve the quality of their designs. Additionally, Fusion 360 has a built-in cloud-based storage and collaboration platform that makes it easy to share and work on designs with other team members.

In terms of compatibilities, both Rhino and Fusion 360 offer compatibility with a wide range of 3D printing hardware and software. Rhino has a plugin called RhinoCAM that allows for seamless integration with CNC (Computer Numerical Control) machines, making it a great choice for those who need to create precision parts. It also has a plugin called Grasshopper that allows users to create parametric designs and automate certain design processes. Fusion 360, on the other hand, has a built-in CAM module that allows for seamless integration with CNC machines, as well as a range of simulation tools for testing the strength and durability of 3D printed parts. Fusion 360 also has a library of pre-built parts and components that can be easily modified and customized to fit specific design requirements.

In terms of compatibility with other software tools, Rhino is known for its flexibility and ease of integration with other software tools, such as Adobe Illustrator and Photoshop. Fusion 360 also offers integration with a range of software tools, including Eagle PCB design software and Netfabb for 3D printing preparation.

Ease of Use

When it comes to ease of use, both Rhino and Fusion 360 have their strengths and weaknesses. Rhino is known for its intuitive interface and user-friendly tools, which allow users to create precise 3D models quickly and easily. The program has a well-designed workspace that can be customized to the user’s preferences, with multiple viewports and tools organized logically and intuitively. Rhino also has a large community of users who have developed helpful resources and tutorials, making it easy for new users to get started and learn the program.

Fusion 360, on the other hand, has a steeper learning curve due to its more complex and feature-rich interface. However, once users become familiar with the program, they appreciate its advanced capabilities and streamlined workflow. Fusion 360’s cloud-based platform allows for easy collaboration and sharing of 3D printing files, and its integration with other software tools and services such as CAM and simulation makes it a powerful all-in-one solution for designing and manufacturing.

Ultimately, the ease of use of Rhino and Fusion 360 will depend on the user’s experience level, specific needs, and personal preferences. Rhino’s intuitive interface and user-friendly tools make it a great choice for beginners and those who prioritize simplicity and ease of use. Fusion 360’s advanced capabilities and integration with other software tools make it a powerful choice for advanced users and those who require a more comprehensive solution.

Cost

The pricing models for Rhino and Fusion 360 are different, and this may be a significant factor for some users when choosing between the two. Rhino has a one-time purchase price, which may be more attractive for those who prefer a one-time investment. The cost of Rhino ranges from $395 for a student/educator license to $995 for a commercial license, with discounts available for upgrades and volume purchases.

In contrast, Fusion 360 has a subscription-based model, which may be more attractive for those who prefer a lower upfront cost and the ability to scale up or down as needed. Fusion 360 offers a free, fully functional personal use license, as well as several subscription options ranging from $495/year for a standard commercial license to $1,495/year for an ultimate license that includes advanced simulation and generative design features.

Both Rhino and Fusion 360 offer value for their respective pricing models and the decision between the two will ultimately depend on the user’s specific needs, preferences, and budget. Rhino’s one-time purchase price may be more attractive for those who have a set budget and do not anticipate frequent updates or upgrades, while Fusion 360’s subscription-based model may be more attractive for those who prefer a lower upfront cost and the ability to scale up or down as their needs change.

Compatibility with 3D Printing Technology

One of the most critical factors to consider when choosing a 3D modeling software program is its compatibility with 3D printing technology. Both Rhino and Fusion 360 are compatible with most 3D printing technologies and file formats.

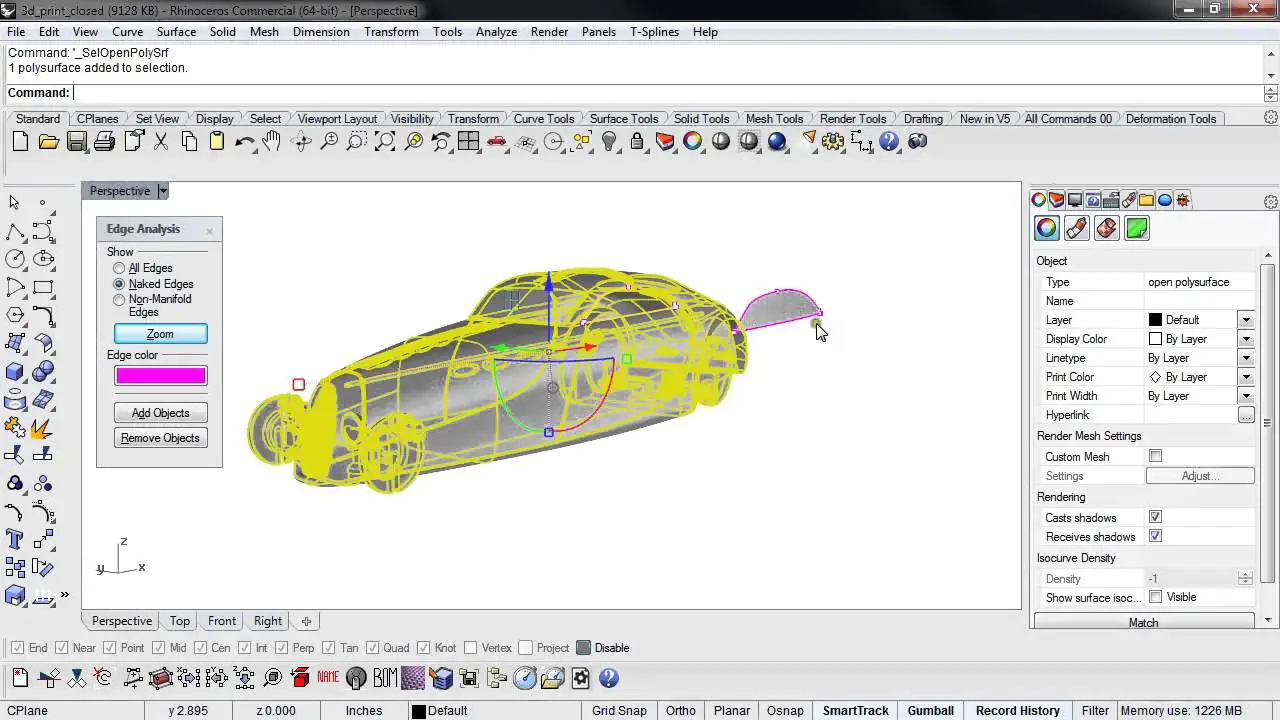

Rhino’s mesh modeling capabilities make it an excellent choice for 3D printing applications. It includes a built-in STL export function, which is the standard file format for 3D printing. Additionally, Rhino’s plugin ecosystem includes several plugins for 3D printing, including tools for slicing, support generation, and file repair.

Fusion 360 is also well-suited for 3D printing applications. Its parametric modeling capabilities can make changes to a model’s dimensions and features, which can be essential for creating parts that fit specifically and provide concrete examples:

For example, if you were designing a custom phone case using Rhino, you could create the case’s overall shape using NURBS modeling and then add details and embellishments using mesh modeling. You could then export the file as an STL and send it to a 3D printer for printing.

Similarly, if you were designing a mechanical part using Fusion 360, you could create the part using parametric modeling and then use the built-in CAM module to generate toolpaths for manufacturing. You could then export the file as an STL or other compatible file format and send it to a 3D printer or other manufacturing processes.

In terms of specific 3D printing technologies, both Rhino and Fusion 360 are compatible with a wide range of printers, including FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering) printers. Both programs also support file formats commonly used in 3D printing, such as STL, OBJ, and 3MF.

While both Rhino and Fusion 360 are capable of creating 3D models that can be 3D printed, there are some differences in how they approach 3D printing. Rhino’s focus on precision and surface modeling makes it an excellent choice for creating complex geometric shapes that require high levels of accuracy. Additionally, Rhino’s extensive plugin ecosystem includes several plugins for 3D printing, such as the RhinoGold plugin for jewelry design and the T-Splines plugin for organic modeling.

Fusion 360, on the other hand, is a more all-in-one solution that includes CAM functionality for generating toolpaths for manufacturing. This makes it an excellent choice for those who need to design and manufacture parts in-house. Additionally, Fusion 360’s cloud-based platform allows for easy collaboration and sharing of 3D printing files.

Rhino’s precision and versatility make it an excellent choice for architects, industrial designers, and jewelry designers who require high-level surface modeling. Fusion 360’s parametric modeling and CAM capabilities make it a great choice for mechanical engineers and those who need to design and manufacture parts in-house.

Conclusion

In conclusion, both Rhino and Fusion 360 are powerful 3D modeling software programs that are well-suited for 3D printing applications. While they have different strengths and weaknesses, both programs offer a range of features and capabilities that make them valuable tools for a wide range of industries and applications. Ultimately, the choice between Rhino and Fusion 360 will depend on the user’s specific needs, preferences, and budget, and both programs offer a range of resources and support to help users get started and make the most of their 3D printing projects.