What is 3D Printing?

3D Printing is also known as additive manufacturing. It is commonly employed in making three-dimensional hardcore solid objects from any type of digital representation. In an additive process, the object is created by laying out successive layers of the object. Each layer is perfectly separated by a thinly sliced cross-sectional area of the object. 3D Printing is the opposite of subtractive manufacturing and needs cutting out a section from metal or plastic, just like a milling machine. It enables perfect presentation and flexibility of even the complex shapes using lesser material than traditional metal manufacturing supplies.

How Does 3D Printing Work?

3D Printing starts with 3D Modeling. You can easily create the ground needed for 3D printing, by using 3D Software. There are several 3D software available in the market. For industrial-grade, open-source software works best. Tinkercad is certified suitable for beginners and is supported by a browser. Furthermore, Tinkercad has a diverse user interface and also allow export option into a printable file i.e. OBJ or STL. Now when you get multiple stored printable file formats, all you need to do is to prepare these for a 3D printer. This step is essentially termed Slicing.

Slicing: Printable File to 3D Printer

‘Slicing’ in 3D Printing Language means to dice up a 3D model into thousands of layers and such a process is done via slicing software. When the file is sliced it is all set to have a taste of the 3D printer. Feeding the file to your 3D printer can be accomplished via SD, USB, or Wi-Fi. The file is now ready to be printed layer after layer.

3D Printing Industry

3D printer was only considered suitable primarily for prototyping and one-off manufacture processes but today it constitutes a whole lot of every field you can name off. The 3D printing technology is transforming into production technology in a clear-cut description of the term being discussed. The largest proportion of 3D printing use is in the industrial sector. The global 3D printing market is said to rise by $41 Billion by the year 2026. Through this massive shift and economic growth, 3D printing is transforming every major industrial cooperation and leading the world to its advanced future.

Examples of 3D Printing

3D printing encompasses a wide variety of material objects and technologies in its favor. Nowadays 3D printing is being employed in whatsoever industry or field you can think of. Such a myriad of different applications is described as under:

A few examples include:

Consumer products, such as eyewear, footwear, design, furniture.

Industrial products like tools, prototypes, functional end-use parts.

Reconstructing fossils

Replicating ancient artifacts

Reconstructing evidence in forensic pathology

Movie props

Dental products

Prosthetics

Architectural scale models

Rapid Prototyping

Companies employ 3D printers to design processes and as a result, transform their designs into creative prototypes since the late 70s. However, 3D printers employed for such a purpose are termed Rapid Prototyping.

Why use 3D Printers for Rapid Prototyping?

The name suggests that the process becomes comparatively faster and much more reliable than the traditional means of prototyping. We are talking about 3D modeling in just a couple of days rather than weeks. Think about how much time and money you get to save through the efficient means of rapid prototyping. Through the process, iterations become simple and cheaper. And most of all you do not need to stress in learning how to use expensive tools or molds. Besides this type, another one named Rapid Manufacturing is employed to save your 3d manufacturing struggles.

Automotive

Car manufacturers have been using 3D printing for decades now and the results are in front of all of us. Such automotive companies print spare parts of cars, tools, jigs, end parts, and even fixtures. This has helped manufacturers to construct on-demand manufacturing and that too at a lower stock rate. The automotive industry has also thrived from keeping up with the latest designs and modeling cycles.

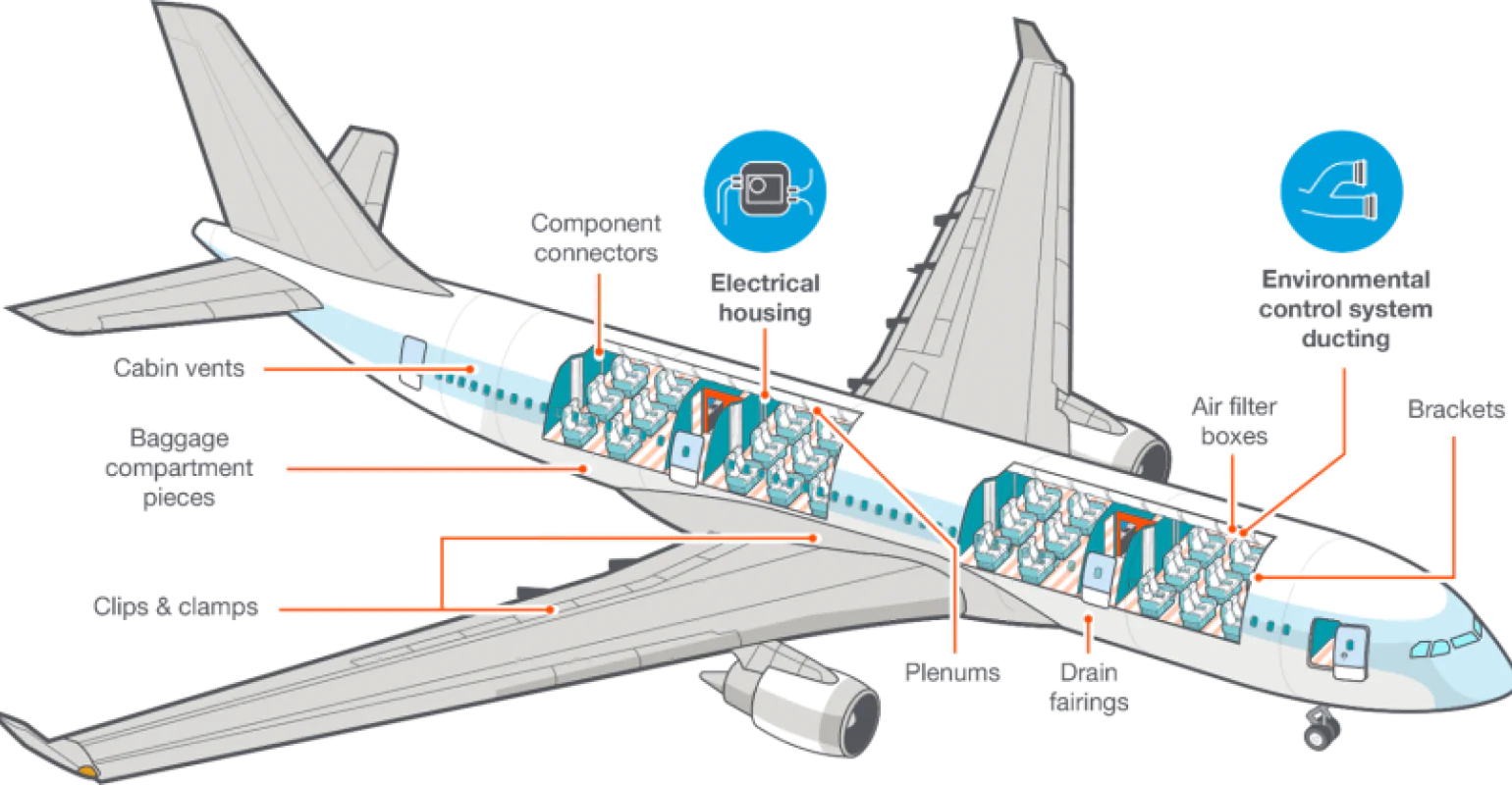

- Aviation

The aviation industry also benefits equally from 3D printing in many diverse ways. GE Aviation uses 30,000 3D printed Cobalt-chrome nozzles for fueling. Such nozzles are essential in all LEAP aircraft engines. Hence, 3D printing is setting up major benchmarks in catering to high and advanced platforms.

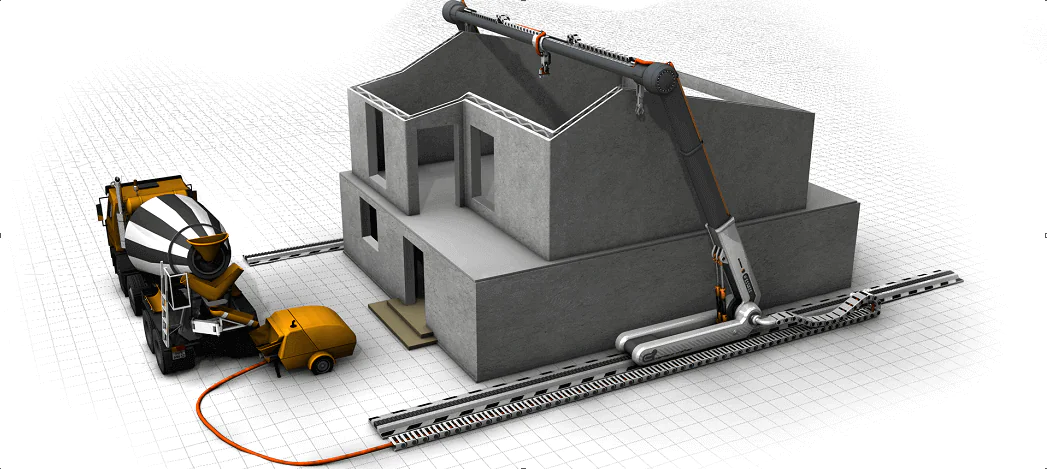

Construction

The construction sector also involves 3D printing in its unique ways. The 3D printed houses are already available in the market. Some companies independently print their construction parts, hence saving a huge amount of cost overturns at their end all thanks to 3D printing.

Footwear

3D Printing has set the record straight in the footwear industry as well. Like for example take Adidas the famous shoe brand, they have a successful 3D printed midsole for Adidas’4D and being printed in larger volumes each day. The total market of 3D printed footwear is estimated to be $5.9 Billion by the year 2029.

Eyewear

The market of 3D printing is continuously shaping shifting to its new and improved form with each passing day. The industry of eyewear is expected to reach $3.4 Billion by the year 2028. Such a rapid increase in the end-user frames has confirmed the fact that 3D printing is a suitable match for production methods of eyewear frames.

Jewelry

There are many kinds of jewelry you get to see in the market. There are two different and unique kinds of jewelry processed via the 3D printer. One by the direct process and the other by the indirect process of manufacture, the direct process involves the direct creation of an object from a 3D design and the other one corresponds to the 3D printed pattern to be created in a mold or casting.

Healthcare

The healthcare sector utilizes 3D printing as implants. 3D printing is a fringe technology in the medical sector but today the case scenario has considerably changed. From the last decade to today there are more than one lacks hip replacements with 3D printed GE Additive.

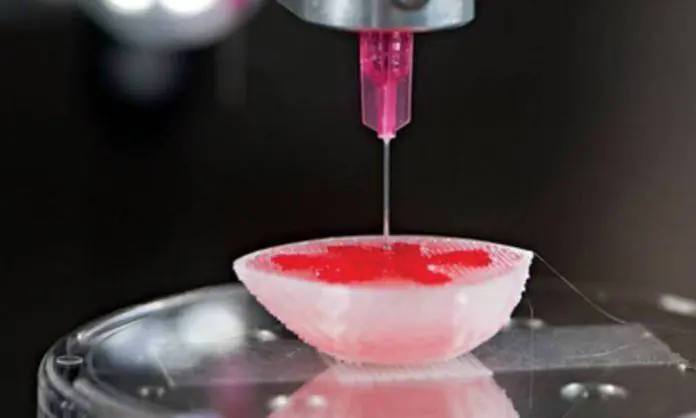

Bio-printing

In Bio-Printing, layers of tissue cells are well deposited in a gel-like medium and slowly built from 3D structures. Such a type of field is referred to as Bio-Printing. Tissue engineering is massively using 3D printing to resolve its organs and body parts formation application to the best use of humanity and animals.

How ITS can help you with 3D Modeling Service?

Information Transformation Service (ITS) has been providing 3D Modeling Services for over a time now. Information Transformation Services knows all about the modern-day industry and its trends in the Online Marketing Business. ITS is light on the budget and heavy in terms of quality and stature. Our highly responsive and interactive team specializes in 3D Product and Asset Modeling Services and will note down every essential detail provided by you and in return turn your dream into a real-life realistic or virtual reality. Information Transformation Service (ITS) also caters to a wide variety of services relating to efficient 3D Modeling and Designing services. If you are interested in ITS 3D Modeling Services, you can ask for a free quote!