Top 8 Benefits of 3D CAD Modeling In Mechanical Engineering Design

If you are facing trouble for creating accurate mechanical drawings by traditional means of drafting then this blog is essentially to teach you how effective 3D CAD Modeling proves for addressing your mechanical modeling concerns. Inaccurate drawings can cost you your valuable money and time. Many firms over the years have shifted to using 3D CAD tools to design flawlessly all mechanical parts during the manufacturing stage. 3D Mechanical Modeling reduces the additional need for redundant designs.

In this age of high maintenance and mechanical operations, the importance of accurate documentation and designing can’t be stressed enough. Engineering drawings are stressfully time-consuming to develop via conventional drafting methods. At the end of the development, there is a considerable chance of error arousal and all the steps need to be revised repeatedly which makes the editing part strenuous. 3D Modeling combined with CAD can create remarkably complex yet precise mechanical models. 3-Dimensional animation tools have become indispensable in engineering designs especially when we talk about the mechanical engineering field.

Here are a few notable benefits of 3D modeling and CAD combined:

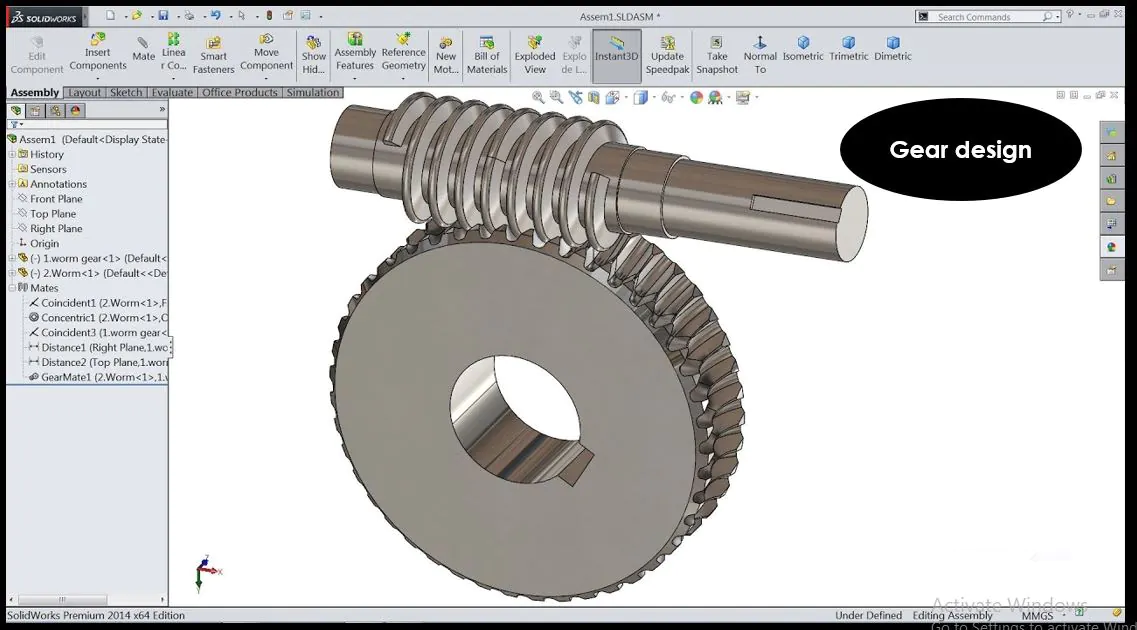

Improvement in The Quality of Design

3D CAD Software is rich in a variety of libraries containing up to 700,000 standard templates which can be used as mechanical components. This feature allows developers and modelers to effectively select designs as per the need of the modeling project. As a result, efficient and accurate execution of mechanical models is made possible in the lowest turnaround time. 3D CAD conclusively eliminates all kinds of deformities and design deviations.

Increases Productivity of The Designers

3D CAD Modeling reduces the tedious and manual parts of the designs. It helps in better visualization of the mechanical components in 3D at the very initial stage. This immensely proves useful to make instant changes. The productivity of the designer is coupled with the reduced number of iterations.

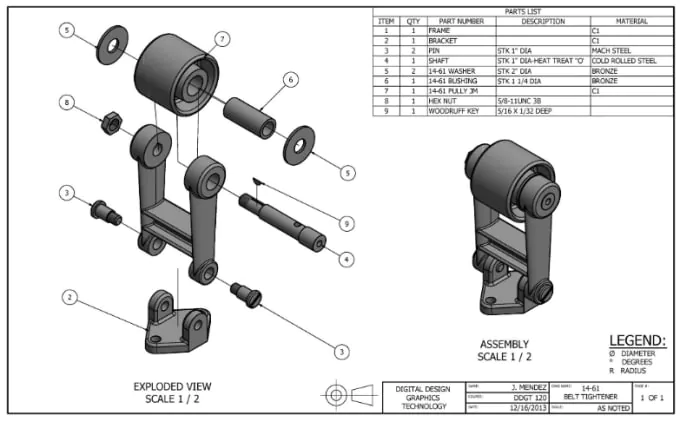

Easier Documentation Process

The documentation stands consistent, detailed, and stands out. The mentioned type of documentation empowers the entire team of designers. It provides a firm basis for mechanical project context understanding. In addition, it equips the modelers to generate an effective problem-solving technique. Without CAD 3D modeling tools, the level of attention required for the documentation process is too nerve-wracking tedious, still, errors can arise as there is no 100% guarantee of accuracy. Hence, it is commendable that 3D CAD modeling tools have made the process more flexible and creative in its way. Things like material specifications, product dimensions, geometric documentation, and bills of materials can be standardized with a detailed drafting process. Furthermore, automation and integration of the procedure have a positive effect on reducing speed and building the quality of the mechanical output.

Maintains Compatibility with International Standards

The ISO has released a standard and comprehensive list of CAD processes. One of the primary objectives is to establish sheer consistency, compatibility, and safety in the drafting process. By adhering to international standards, all organizations ensure that services and products are safer to use and more effective in quality. Mechanical engineered designs are prepared in 3D CAD that complies with global standards just like ANSI, CSN, BSI, and DIN. The standards are more important than anything else as products are closely assembled from mechanical components which are made in different countries and sold across borders.

Redraws The Design Automatically

When using all different traditional drawing techniques, designers often face problems to draw the hidden parts of products or components. 3D CAD is the solution to this problem, as it eliminates the percentage of error while redrawing dashes and lines of the hidden or underlying machine parts of the design.

Reduces The Design Cost and Time

The most important resources which a company can acquire while utilizing CAD Modeling tools are time, effort, and money, As CAD modeling platforms support built-in standard templates and design layouts. This significantly helps mechanical engineers to not start from scratch every time while creating a new design. Hence, remodeling and conceptual detailed designing become way easier with CAD modeling software. With ever-growing market competition, time is money! All the top CAD companies offer the facility to test tolerance and other stress factors of a project design before it is even built. In this way, most severe design problems are neglected before the construction even begins.

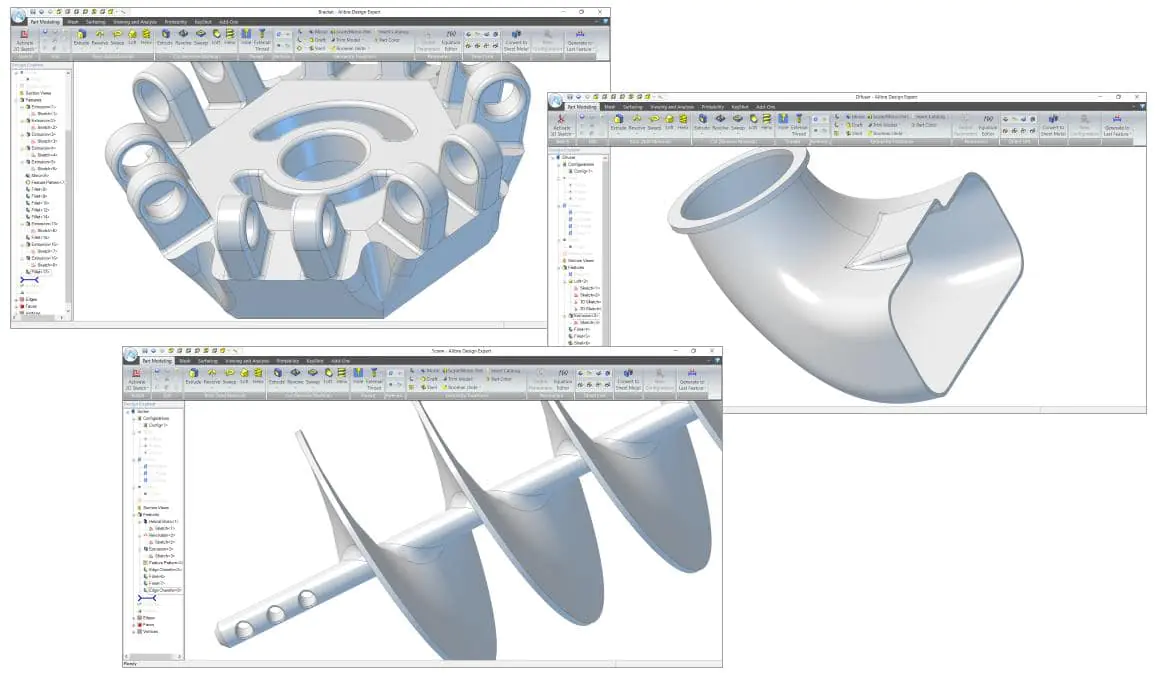

Facilitates Effective Visualization to Clients

Every component of a mechanical model can be animated with the help of 3D CAD modeling tools. All mechanical properties and functionalities are completely understood in the best possible way. 3D CAD modeling allows every type of modeling team like the engineering procurement, operators-owners, and construction companies to visualize the final product plan in a suitable format. Thus, based upon the intelligent design plan you can make more data-driven decisions and reliable business forecasts. Every individual design elements can be changed as per the client’s customized needs. You can efficiently figure out all ‘what-if’ modeling scenarios more wisely and reduce possible error margin. Non-CAD and non-design stakeholders can also be a part of the process by participating in the virtual model creation. With new, polished, improved, and interactive visual representations, you can surely win the clients by giving them a virtual tour of the final product design.

Saves Drawing and Data for Future

CAD and 3D Modeling can save all mechanical engineer’s projects, designs and work effectively for further reference and access. These images can be utilized and offered to different clients in future endeavors to mark unique project deliverance. Mechanical design has now been revolutionized to its core. The invention of CAD software has prompted high quality and scalable textures and lighting to make the designs look more real. The use of CAD with 3D modeling enables mechanical engineers to sort out any technical issue within mechanical designs successfully.

Conclusion:

3D CAD modeling software makes its use in almost every industrial sector, be it automobile, machining, or any other. The modeling platform makes sure that contemplated designs are translated to real-time workable models. Other conventional means are very costly and it is difficult to avoid mistakes while converting designs into a product which can afterward prove very dangerous and in the worst-case scenario can lead to major accidents. 3D modeling offers world-class solutions to all these modeling complexities and uses CAD for further enhancing the clarity, speed, and accuracy of the mechanical model in the best manner. In recent years, the proliferation of cloud-based Internet solutions, other various devices, and platforms have widened the scope of 3D CAD modeling to a much broader user base. Thus, 3D CAD modeling is practically more applicable and useful for new verticals such as mechanical engineering.

How ITS Can Help You With 3D Mechanical Modeling Service?

Information Transformation Service (ITS) provides a wide variety of services relating to efficient Mechanical Modeling and Designing Service. Our organized and well-managed ITS Team specializes in 3D modeling utilizing the latest software and expert recommendations. From blow-up to explosive views of any mechanical parts ITS Team professionally handles all mechanical projects in the fastest turnaround time to help your business expand exponentially. If you are interested in ITS 3D Mechanical Modeling Software, you can ask for a free quote!