Can SolidWorks Be Used For Sheet Metal Design

SolidWorks is a widely used computer-aided design (CAD) software known for its versatility and ease of use; popular among engineers, designers, and manufacturers due to its wide range of features and tools that can be utilized for various design projects. One application of SolidWorks that interests many is its ability to handle sheet metal design. Sheet metal is commonly used in many industries, including automotive, aerospace, and construction. However, designing sheet metal parts and assemblies can be challenging due to their unique characteristics, such as bending, forming, and cutting. In this blog, we will explore whether SolidWorks can be used effectively for sheet metal design and the various features and tools available within the software that can assist in the design process.

Features and Tools Available Within SolidWorks:

SolidWorks offers a range of features and tools that can be utilized for sheet metal design. Some of these features are specific to sheet metal design, while others are more general-purpose tools that can be adapted for use in sheet metal design.

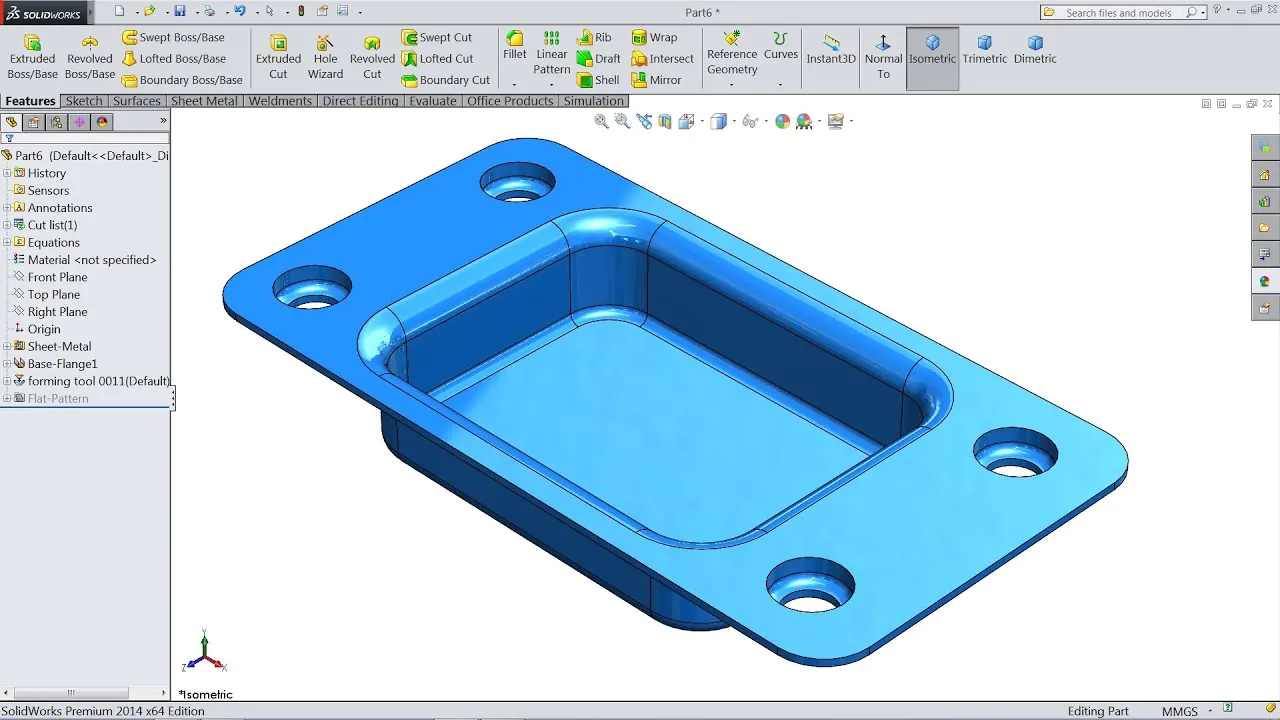

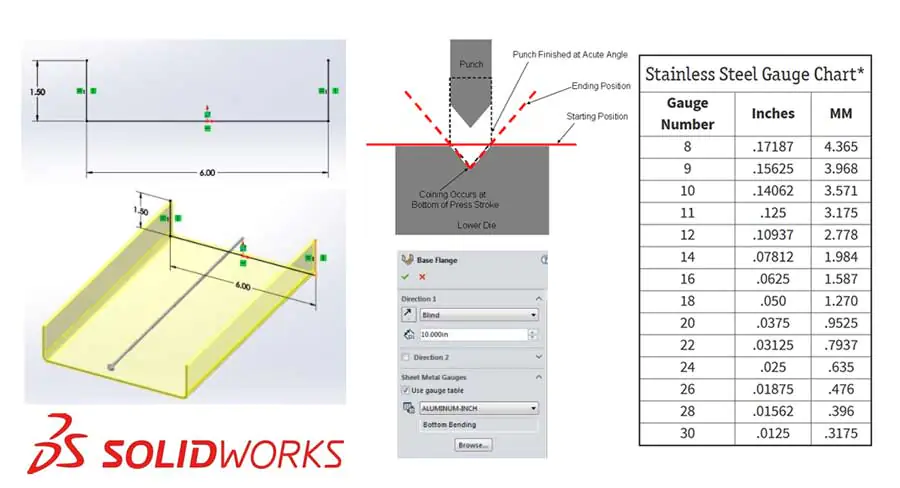

Sheet Metal Wizard

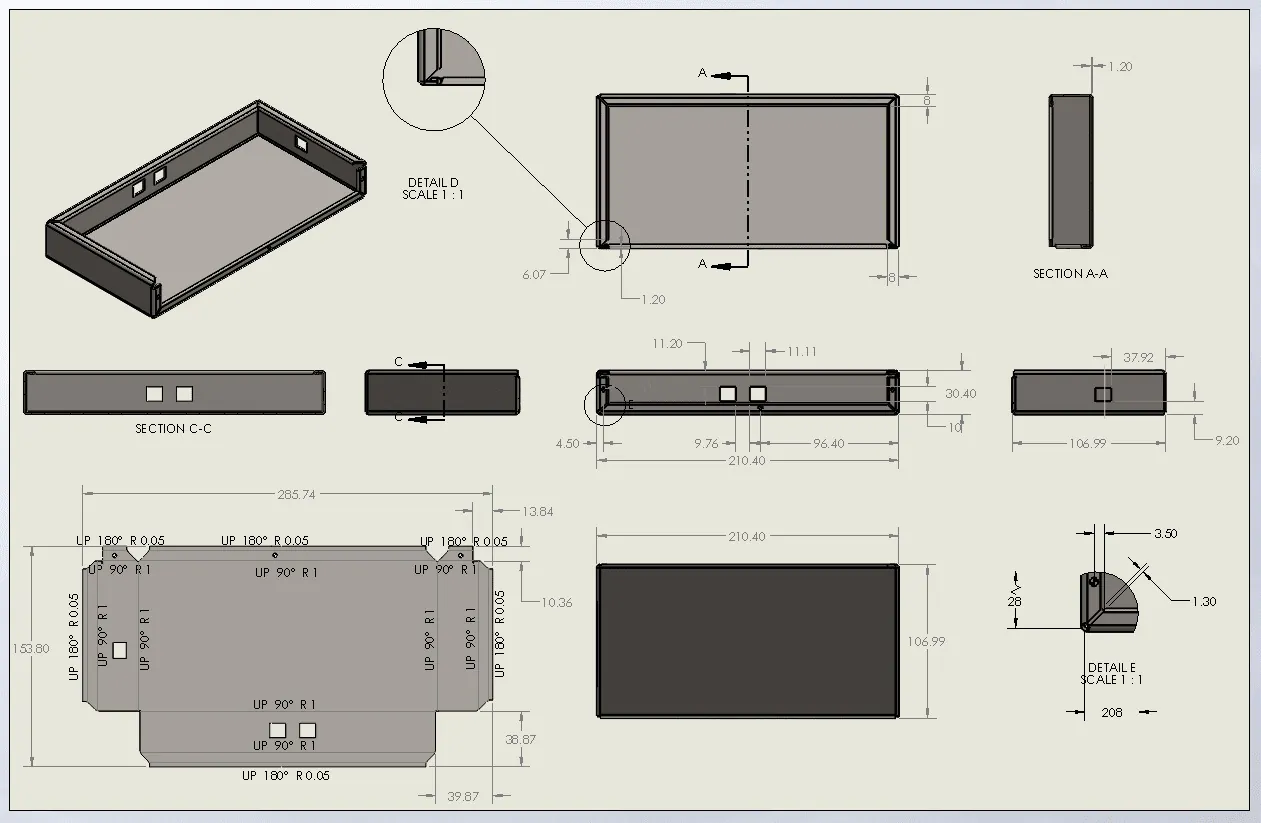

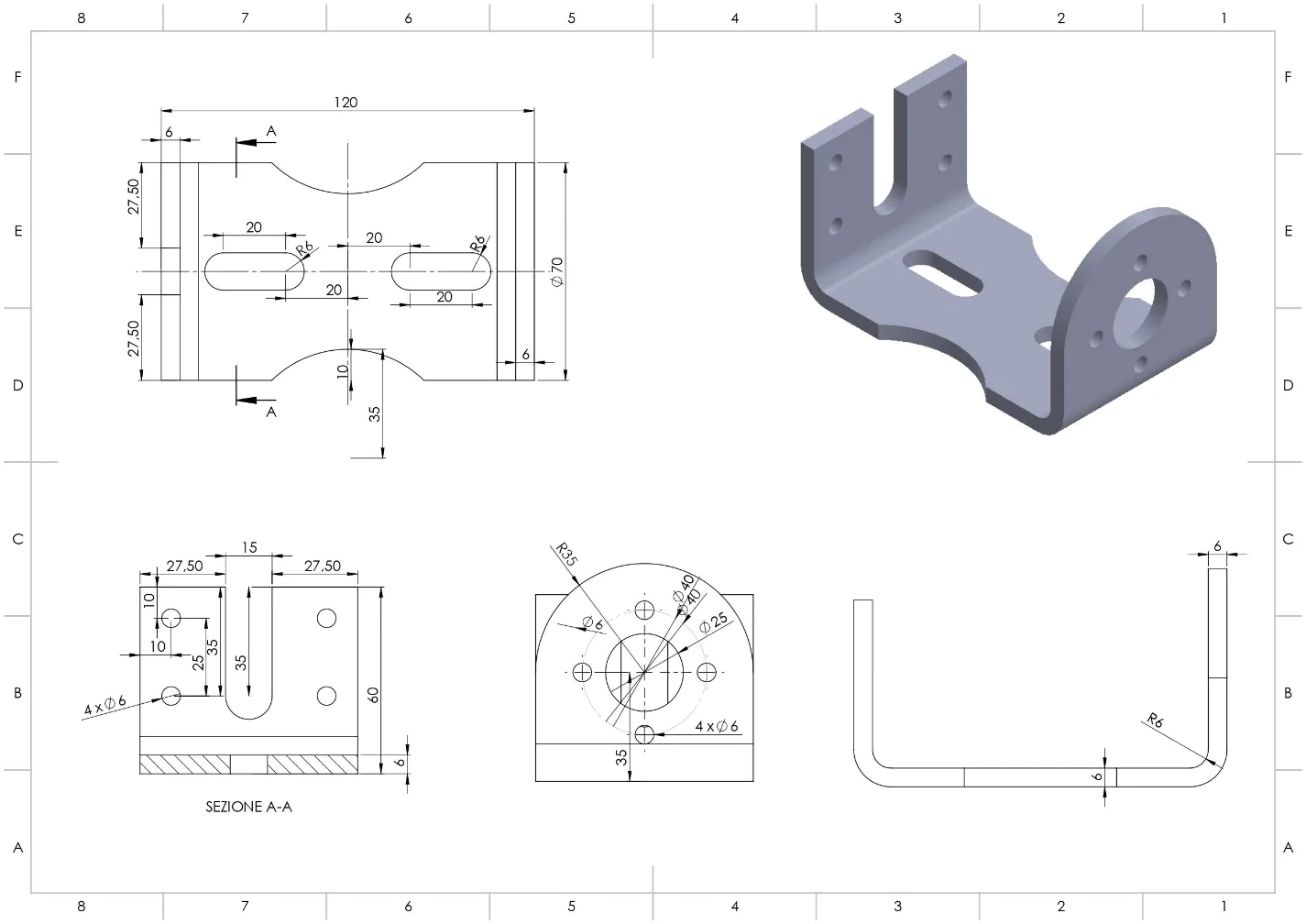

The Sheet Metal Wizard is a SolidWorks tool allowing users to create sheet metal parts from scratch. This tool provides a step-by-step process for creating sheet metal parts, allowing users to specify parameters such as material thickness, bend radius, and corner relief. It can also automatically calculate the flat pattern of the part, which creates the 2D profile for laser cutting or punching.

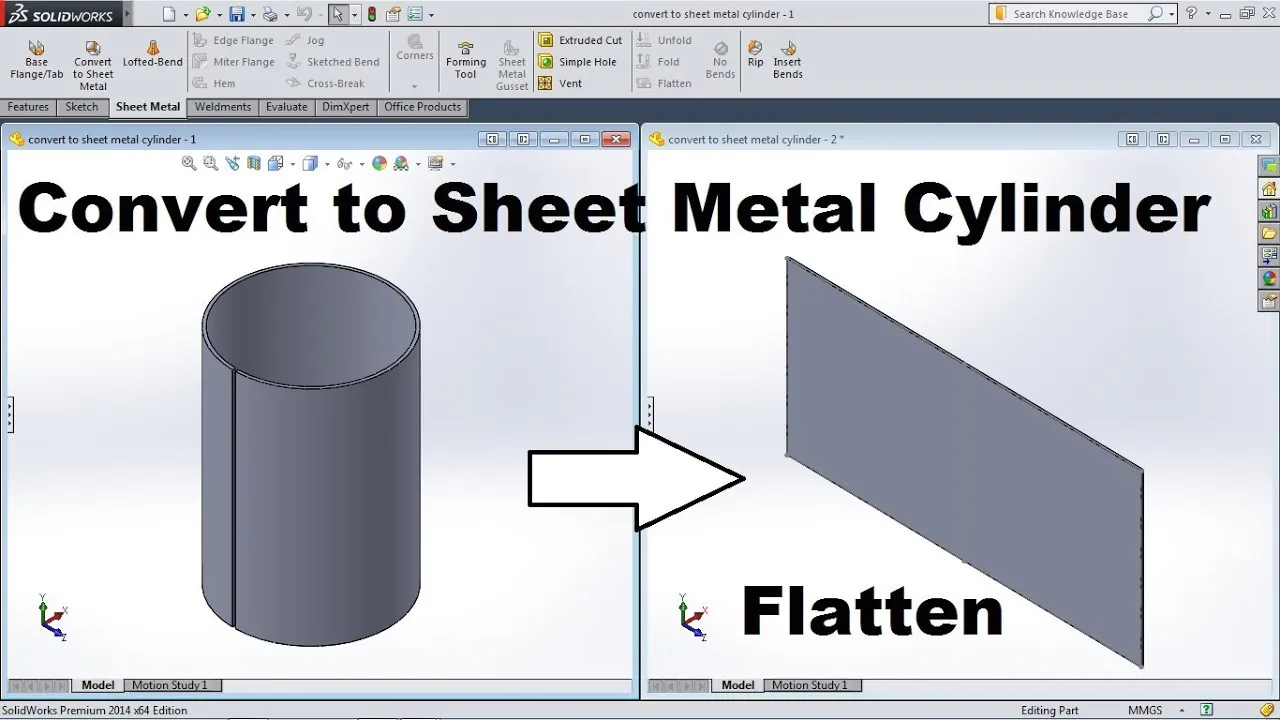

Convert to Sheet Metal

Convert to Sheet Metal tool allows users to convert a solid part into a sheet metal part, preserving its features and geometry while adding sheet metal-specific parameters such as bend radius and relief cuts.

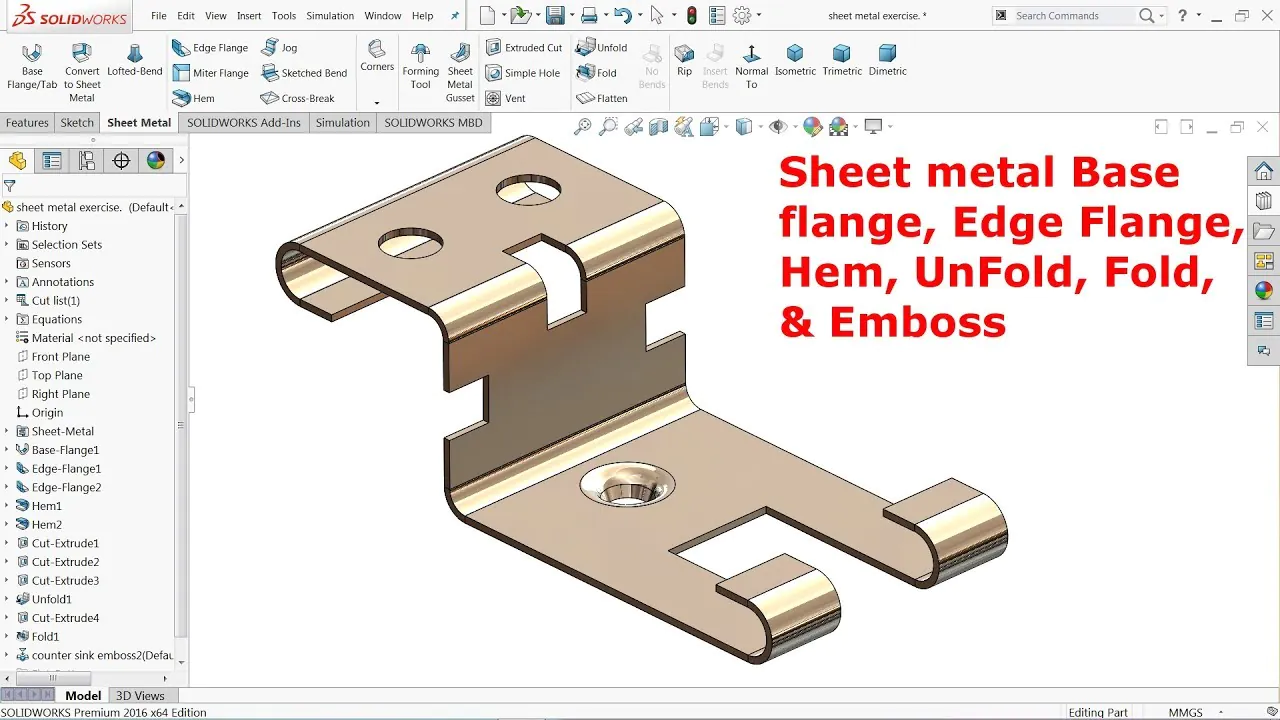

Flange and Hem

SolidWorks’s Flange and Hem tools create bends and hems in sheet metal parts. The Flange tool allows users to bend a sheet metal part, while the Hem tool creates a rolled edge or hem. Both tools can be customized to specify the bend radius, relief cuts, and other parameters.

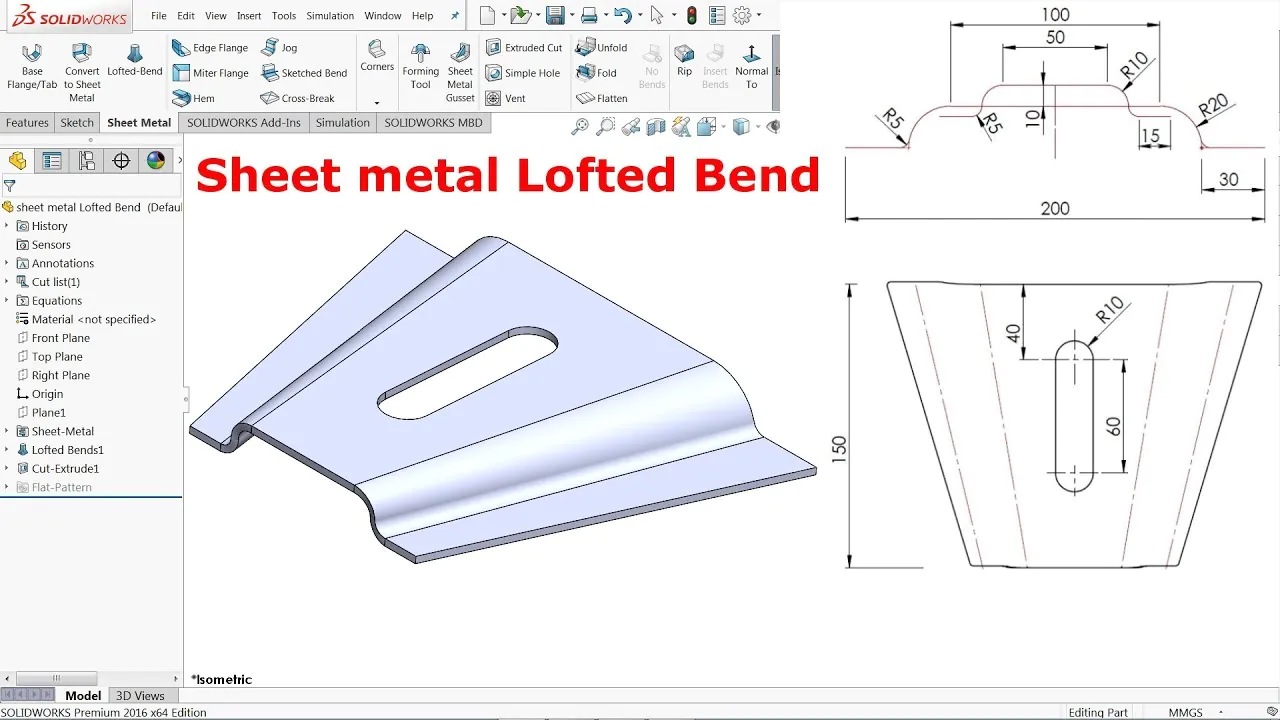

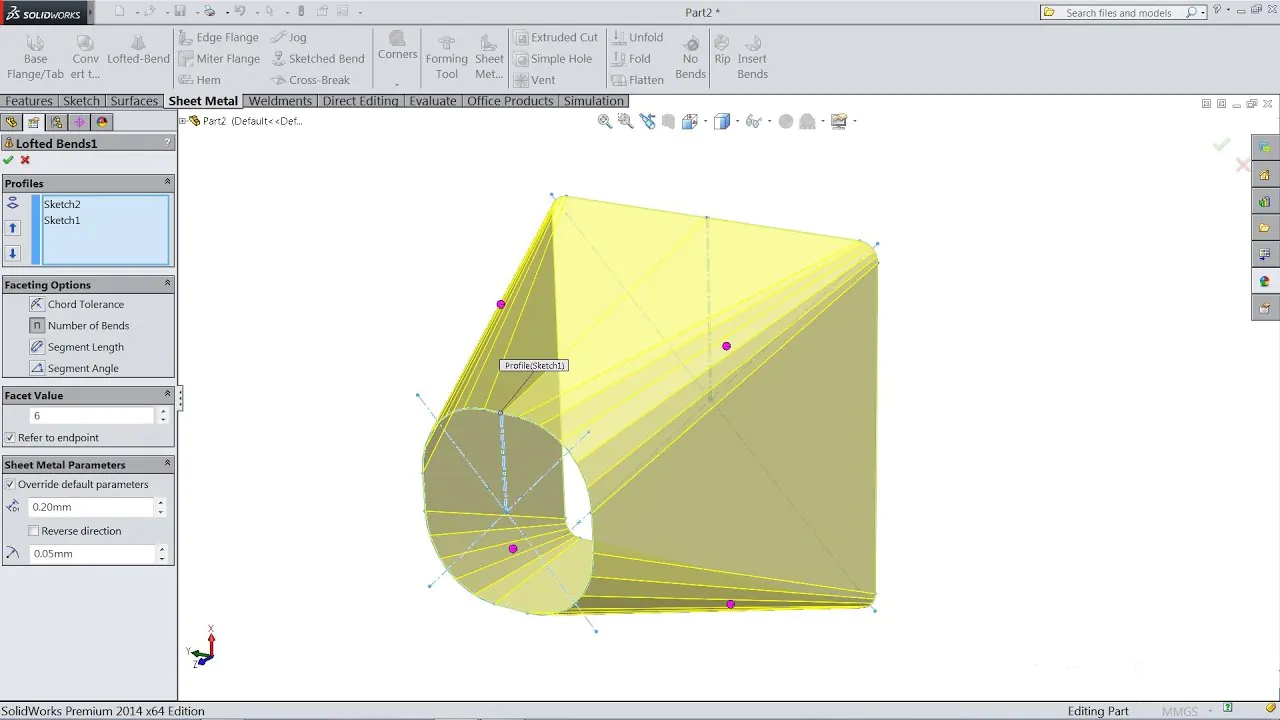

Lofted Bend

The Lofted Bend tool in SolidWorks creates sheet metal parts with curved or twisted shapes. This tool allows users to create a series of bends that follow a curved path, such as a tube or cone. The Lofted Bend tool can create complex sheet metal parts that are difficult to produce in traditional bending methods.

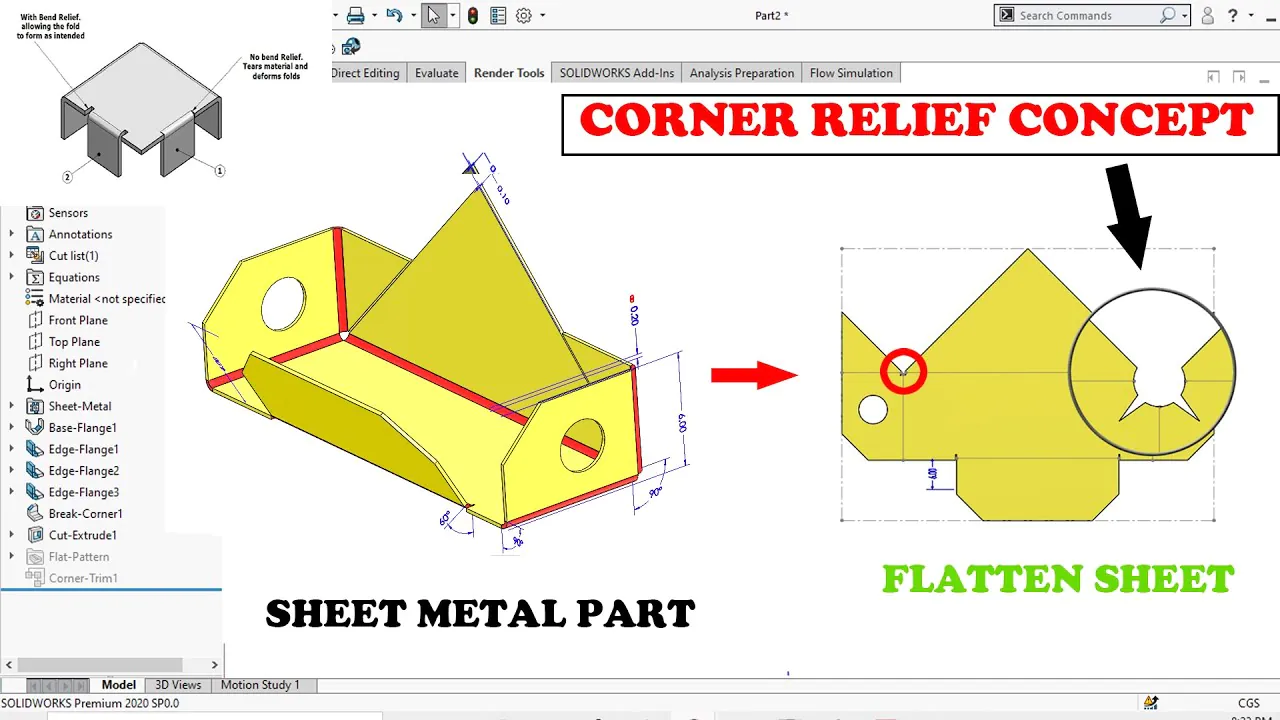

Rip and Corner Relief

SolidWorks’s Rip and Corner Relief tools create relief cuts in sheet metal parts. These relief cuts reduce stress and prevent cracking during the bending process. The Rip tool creates a cut that extends from an edge to a bend, while the Corner Relief tool creates a cut at the intersection of two bends.

Swept Flange

The Swept Flange tool in SolidWorks creates sheet metal parts with complex curves or shapes. This tool allows users to create a flange that follows a path, such as a curved surface or a helix. The Swept Flange tool can create sheet metal parts uniquely shaped or curvature.

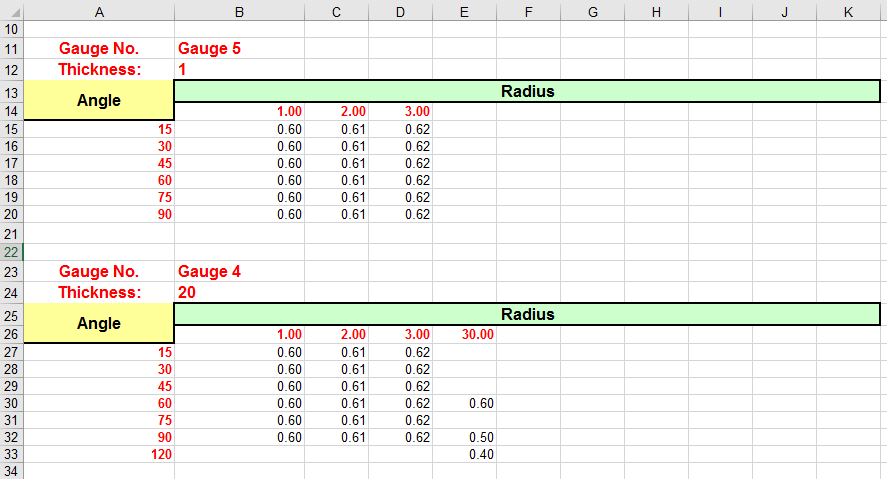

Bend Table

The Bend Table feature in SolidWorks allows users to define and customize the bend allowance and deduction values for specific materials and thicknesses. This tool can ensure that the correct material is used for each bend, preventing material waste and reducing costs.

Sheet Metal Gauge Table

The Sheet Metal Gauge Table feature in SolidWorks allows users to define and customize the sheet metal gauge values for specific materials. This tool can ensure that the correct material thickness is used for each part, which can help prevent part failure and improve overall quality.

Flat Pattern

The Flat Pattern feature in SolidWorks creates a 2D profile of a sheet metal part, which can be used for laser cutting or punching. This tool can automatically calculate the flat pattern based on the geometry and the specified bend allowances. The Flat Pattern tool can save time in the production process, allowing users to generate a 2D profile for cutting quickly.

The Benefits and Limitations of Using SolidWorks for Sheet Metal Design:

SolidWorks is a powerful CAD software that offers a range of benefits and limitations for sheet metal design. While it may not have the same level of functionality as specialized sheet metal design software, it offers an accessible and cost-effective solution for many businesses and designers. By carefully considering the software’s strengths and weaknesses, designers can determine if SolidWorks is the right tool for their specific sheet metal design needs.

Benefits of Using SolidWorks for Sheet Metal Design:

Easy to Use:

SolidWorks is a user-friendly software that is easy to learn, making it accessible to designers of all skill levels. The software’s intuitive interface and comprehensive documentation make it easy for users to quickly get up to speed on the various features and tools available for sheet metal design.

Efficient Design Process:

SolidWorks features and tools help streamline the sheet metal design process. For example, the software’s Sheet Metal Wizard and Convert to Sheet Metal tools can help designers quickly create accurate sheet metal parts from scratch or convert existing solid parts to sheet metal parts.

Accurate Designs:

SolidWorks offers powerful simulation and analysis tools to help designers ensure that their sheet metal designs are accurate and efficient. The software’s simulation capabilities allow users to test their designs for strength, durability, and performance. At the same time, its automated flat pattern generation tool can help eliminate costly errors in the manufacturing process.

Integration with Other Software:

SolidWorks integrates with various other software programs, including CAM software and product data management (PDM) systems, making it easy for designers to collaborate and share their designs with other team members.

Cost-effective:

SolidWorks offers a cost-effective solution for sheet metal design, particularly for small to medium-sized businesses. The software’s licensing and subscription options allow businesses to tailor their investments to their needs and budgets.

Limitations of Using SolidWorks for Sheet Metal Design:

Limited Sheet Metal Functionality:

While SolidWorks offers a range of sheet metal-specific features, it may have a different level of functionality than specialized sheet metal design software. Some advanced sheet metal design features, such as unfolding and nesting, may not be available in SolidWorks.

Steep Learning Curve for Advanced Features:

While SolidWorks is easy to use for basic sheet metal design tasks, some of its more advanced features may have a steep learning curve. That can require additional time and training for designers to leverage the software’s capabilities fully.

Performance Issues with Large Assemblies:

SolidWorks can experience performance issues when working with large assemblies, particularly when using sheet metal-specific features and tools, resulting in slower load times, reduced responsiveness, and increased likelihood of crashes.

Requires a Powerful Computer:

SolidWorks is a resource-intensive software that requires a powerful computer to run effectively. That can be a barrier to entry for smaller businesses or designers working on older or less powerful hardware.

Limited Control over Certain Parameters:

While SolidWorks offers a range of customizable parameters for sheet metal design, some parameters, such as the position of bend lines, may not be as adjustable as in specialized sheet metal design software.

Tips to Optimize SolidWorks for Sheet Metal Design

Customize the User Interface:

SolidWorks allows users to customize the user interface to their specific needs. Users can add frequently used tools to the toolbar, create custom keyboard shortcuts, and customize menus to streamline their workflow.

Take Advantage of Sheet Metal-Specific Features:

SolidWorks exhibits features and tools specifically designed for sheet metal design. These include the Sheet Metal Wizard, which can help users quickly create sheet metal parts from scratch, and the Flange and Hem tools, which can help add bends and hems to parts. These features allow users to save time and ensure their designs are accurate.

Use Simulation and Analysis Tools:

SolidWorks offers a range of simulation and analysis tools to help users ensure their sheet metal designs are accurate and efficient. The software’s simulation capabilities allow users to test their designs for strength, durability, and performance. At the same time, its automated flat pattern generation tool can help eliminate costly errors in the manufacturing process.

Customize Bend Allowance Values:

SolidWorks allows users to customize bend allowance values to ensure their sheet metal parts are manufactured correctly. By entering the correct bend allowance values, users can ensure their designs are accurate and eliminate the need for costly trial and error during the manufacturing process.

Manage Large Assemblies:

SolidWorks can experience performance issues when working with large assemblies. To optimize the software for sheet metal design, users should consider breaking down large assemblies into smaller sub-assemblies, using simplified configurations, and optimizing the display performance settings.

Stay Up to Date with Software Updates:

SolidWorks regularly releases software updates that can help improve the software’s performance and add new features and tools. By staying updated with these updates, users can ensure they are taking advantage of the latest technological advancements.

Attend Training and Workshops:

SolidWorks offers a range of training and workshop programs to help users learn how to optimize the software for their specific needs. By attending these programs, users can improve their proficiency with the software and learn best practices for sheet metal design.

Conclusion

Overall, SolidWorks is a powerful software tool that can be used for sheet metal design. Its enormous features, tools, and simulation and analysis capabilities make it a valuable asset for sheet metal designers. Users can improve their efficiency and accuracy by optimizing the software, resulting in better designs and a more streamlined manufacturing process.