How Wet Scrubbers Enhance Particulate Removal Efficiency In Manufacturing

In the industrial and manufacturing sectors, maintaining air quality is crucial not only for regulatory compliance but also for the health and safety of workers. Wet scrubbers are among the most effective air purification technologies, specifically designed to remove particulate matter from exhaust gases. These systems operate by introducing a scrubbing liquid—typically water or a chemical solution—that captures and neutralizes pollutants. The wet scrubber’s ability to handle high-temperature gases and a variety of particle sizes makes it particularly versatile for diverse industrial applications. By enhancing particulate removal efficiency, wet scrubbers play a key role in downsizing emissions and improving overall air quality. To understand how wet scrubbers achieve such high efficiency, it is essential to delve into their operating mechanisms, the types of particles they target, and the factors that influence their performance. For more in-depth insights into wet scrubber particulate removal efficiency and how wet scrubber removes particulate matter, visit Https://torch-air.com/blog/wet-scrubber-particulate-removal.

Mechanisms Of Particulate Removal In Wet Scrubbers

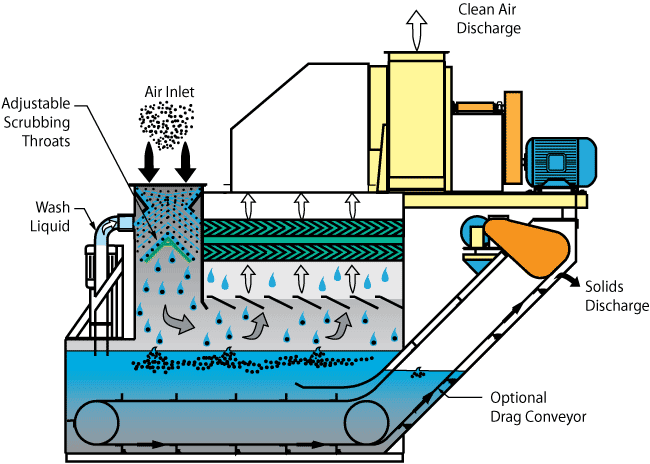

Basic Operation of Wet Scrubbers

Wet scrubbers work by bringing contaminated gas into contact with a liquid, typically water, to remove particulate matter. The gas stream is forced through a scrubbing liquid, where particles are captured and dissolved. This process enhances the wet scrubber removal efficiency, ensuring cleaner emissions.

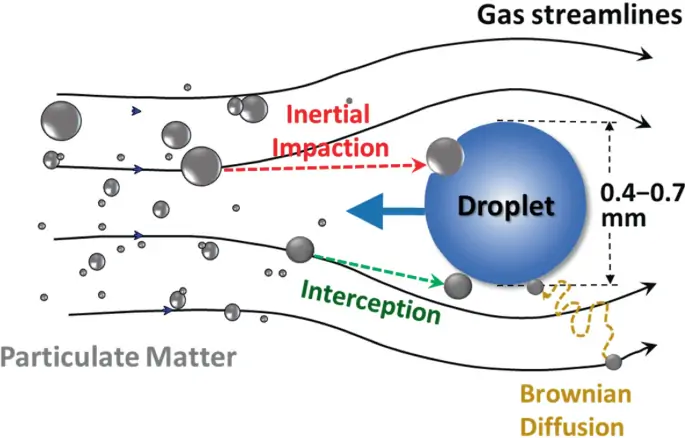

Particulate Capture and Removal

The wet scrubber’s removal efficiency depends on the interaction between the gas and liquid phases. As the gas stream enters the scrubber, it is sprayed with the scrubbing liquid, creating a surface for particles to adhere to. The liquid then traps and removes these particles from the gas stream. Wet scrubbers are particularly effective at removing fine particles that are difficult to capture with other filtration methods.

Advantages of Wet Scrubber Technology

Wet scrubbers are highly efficient in removing a wide range of particle sizes and types. They can handle high temperatures and corrosive gases, making them suitable for various industrial applications. To learn more about how wet scrubbers remove particulate matter and the advantages of wet scrubber technology, visit Https://torch-air.com/blog/wet-scrubber-particulate-removal.

Factors Influencing Wet Scrubber Removal Efficiency

Scrubbing Liquid Properties

The properties of the scrubbing liquid play a significant role in determining the wet scrubber’s particulate removal efficiency. Liquids with higher viscosity and specific chemical properties can enhance the capture of particulate matter. The choice of scrubbing liquid depends on the type of pollutants and the specific industrial application.

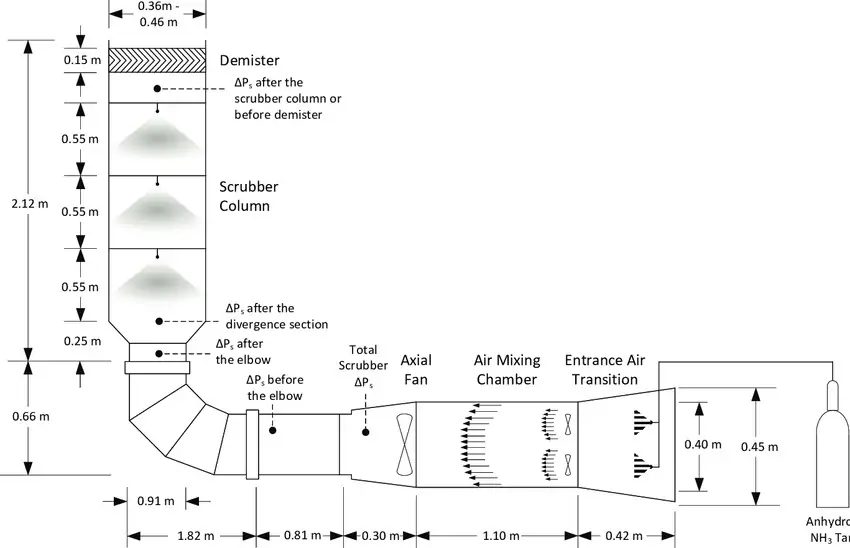

Gas Flow Rate and Pressure

The efficiency of a wet scrubber is also influenced by the gas flow rate and the pressure at which the gas enters the scrubber. Higher gas flow rates can improve contact between the gas and the scrubbing liquid, leading to better particulate removal. However, if the flow rate is too high, it may reduce the contact time, decreasing overall efficiency.

Design and Configuration

The design and configuration of the wet scrubber, including the size, shape, and arrangement of internal components, are critical for optimal performance. Properly designed scrubbers ensure maximum contact between the gas and scrubbing liquid, enhancing the removal of particulate matter. Recurring supervision and adjustments are necessary to maintain high removal efficiency.

For further details on optimizing wet scrubber performance and how wet scrubber removes particulate matter, visit Https://torch-air.com/blog/wet-scrubber-particulate-removal.

Types Of Particles Removed By Wet Scrubbers

Particulate Matter (PM) Categories

Wet scrubbers are effective in removing various types of particulate matter (PM), including PM10 and PM2.5. PM10 consists of particles with diameters less than 10 micrometers, while PM2.5 includes finer particles with diameters less than 2.5 micrometers. These particles can originate from industrial processes, combustion, and other sources.

Dust and Smoke

Wet scrubbers excel at removing dust and smoke particles from industrial exhaust gases. Dust particles, often generated from processes like grinding, cutting, and material handling, can be efficiently captured by the scrubbing liquid. Smoke particles, typically resulting from combustion processes, are also effectively removed, improving air quality.

Chemical Vapors and Mists

In addition to solid particulates, wet scrubbers can remove liquid droplets and chemical vapors. This includes acidic gases like sulfur dioxide (SO2) and ammonia (NH3), which are neutralized by the scrubbing liquid. The ability to handle both particulate and gaseous pollutants makes wet scrubbers versatile in various industrial applications.

For more insights into what particles does a wet scrubber removes and how wet scrubber particulate removal efficiency contributes to environmental health, visit Https://torch-air.com/blog/wet-scrubber-particulate-removal.

Benefits Of Using Wet Scrubbers In Manufacturing Environments

Enhanced Air Quality

Wet scrubbers significantly improve air quality in manufacturing environments by efficiently removing particulate matter and gaseous pollutants. This leads to a healthier workplace, lowering the hazard of respiratory disorders and other health issues among workers. Cleaner air also contributes to better overall environmental conditions.

Regulatory Compliance

Industries are subject to stringent environmental regulations regarding emissions. Wet scrubbers help manufacturers meet these standards by ensuring high particulate removal efficiency. Compliance with these rules not only avoids legal liabilities but also indicates a commitment to environmental responsibility and sustainable practices.

Operational Versatility

Wet scrubbers are adaptable to various industrial processes and pollutants, making them suitable for a wide range of manufacturing applications. Whether dealing with high-temperature exhaust gases or corrosive materials, wet scrubbers can be customized to handle specific challenges. This versatility enhances their utility and effectiveness in diverse settings.

Economic Advantages

Investing in wet scrubber technology can lead to long-term cost savings. By reducing the portion of contaminants released, firms can minimize potential fines and decrease the need for costly repairs and maintenance associated with poor air quality. Additionally, efficient particulate removal can improve the lifespan and performance of other machinery and equipment.

For more details on the benefits of wet scrubbers in industrial settings and what particles does a wet scrubber removes, visit Https://torch-air.com/blog/wet-scrubber-particulate-removal.

Optimizing Wet Scrubber Performance For Maximum Efficiency

Regular maintenance and inspection

are crucial to ensure wet scrubbers operate at peak efficiency. Routine checks help identify and address issues such as blockages, wear and tear, and malfunctioning components. Regular cleaning of the scrubbing liquid and nozzles is essential to maintain optimal particulate removal efficiency.

Proper Scrubbing Liquid Management

The choice and management of the scrubbing liquid significantly impact the performance of wet scrubbers. It’s important to select the appropriate scrubbing liquid based on the specific pollutants being targeted. Additionally, monitoring and maintaining the correct concentration and pH levels of the scrubbing liquid can enhance its effectiveness in capturing and neutralizing particulate matter.

Optimizing Gas Flow Rates

Adjusting the gas flow rates can improve the interaction between the contaminated gas and the scrubbing liquid, leading to better particulate removal. Finding the optimal balance is key, as too high a flow rate can reduce contact time, while too low a rate can decrease overall efficiency. Ensuring proper gas flow rates tailored to specific industrial needs is essential.

Advanced Monitoring Systems

Implementing advanced monitoring systems can significantly enhance wet scrubber performance. These systems provide real-time data on variables such as gas flow rates, pressure, and scrubbing liquid properties. By continuously monitoring these parameters, industries can make timely adjustments to maintain high removal efficiency and overall system performance.

Conclusion:

In conclusion, wet scrubbers are indispensable tools in industrial air purification, efficiently removing particulate matter and enhancing overall air quality. Their versatile nature, coupled with advanced mechanisms and optimization techniques, ensures optimal performance in diverse manufacturing environments. By understanding the mechanisms of wet scrubbers and implementing proper maintenance and monitoring practices, industries can maximize wet scrubber particulate removal efficiency and reap the environmental and economic benefits they offer. For more detailed insights and guidance on optimizing wet scrubber performance, visit https://torch-air.com/blog/wet-scrubber-particulate-removal.