How 3D Modeling Improves Product Development Efficiency in 2026

In 2026, companies across manufacturing, engineering, robotics, and consumer technology face unprecedented pressure to accelerate product development. Supply chains are tighter, customer expectations are higher, and the market demands rapid innovation with minimal tolerance for design or production errors. At the same time, products themselves have become more complex — multi-material assemblies, embedded electronics, advanced aerodynamics, ergonomic constraints, and miniaturized components are increasingly the norm.

These pressures have pushed organizations to re-evaluate how products are designed and validated. As a result, 3D modeling has evolved from a design convenience into a mission-critical engineering tool. According to a 2025 Deloitte study, companies that integrate advanced 3D modeling workflows reduce development cycles by up to 30% and cut prototyping costs by 35–45%. Combined with simulations and digital twins, 3D modeling now serves as the core foundation for efficient, low-risk product development.

The New Reality of Product Development in 2026

Modern product development cycles no longer rely on long timelines and multiple physical prototypes. The competitive landscape requires:

Faster design iterations

Precision engineering before fabrication

Cross-functional collaboration between distributed teams

Immediate validation through simulation and digital testing

In 2026, engineering teams increasingly adopt “digital-first manufacturing,” where 3D models are not an output of the design process — they are the design process. Every decision, from aerodynamics to injection-molding feasibility, is evaluated digitally long before material is ever ordered.

Companies that fail to implement advanced modeling workflows face bloated development budgets, higher error rates, and increased time-to-market, making them uncompetitive in fast-moving industries.

Modern product organizations are increasingly turning to specialized external partners to keep up with these accelerated timelines. Instead of hiring additional full-time staff or overloading internal engineers, many teams now collaborate with expert 3d modeling companies that provide production-ready CAD models, simulation-optimized geometry, and industry-standard digital twins. This approach allows companies to reduce bottlenecks, improve data accuracy, and scale development capacity on demand — a crucial advantage in 2026’s hyper-competitive environment.

Why 3D Modeling Has Become a Critical Tool

Eliminating Design Errors Before Prototyping

Legacy 2D drawings introduce ambiguity and leave room for costly mistakes. In contrast, high-precision 3D models:

reveal geometry conflicts,

prevent misalignment between components,

ensure assemblies fit without interference,

and highlight manufacturability issues early.

This alone can save months of redesign and thousands of dollars in wasted prototypes.

Reducing Physical Prototype Costs

Prototypes remain important — but far fewer are needed.

Simulation-ready 3D models allow engineers to test:

thermal loads,

fluid flow,

mechanical stress,

tolerances and clearances,

and dynamic movement.

As a result, full-scale physical testing is performed only at the final validation stage, dramatically reducing material and labor expenses.

Improving Cross-Team Collaboration

Engineering, design, production, and QA teams now work inside the same digital environment.

Shared 3D models:

streamline communication,

eliminate translation errors between departments,

and ensure that every team operates on real, verifiable geometry.

Faster Iteration Cycles and Real-Time Validation

3D modeling accelerates iteration by enabling rapid adjustments to features, dimensions, and materials.

Combined with AI-assisted design tools, companies can explore dozens of variations in minutes rather than weeks.

How 3D Modeling Increases Efficiency Across the Entire Product Lifecycle

1. Concept & Design

Teams quickly convert sketches or scan data into manufacturable parametric models. Early geometry exploration allows better decision-making and more accurate feasibility studies.

2. Engineering & Simulation

Structural, thermal, flow, and fatigue simulations rely entirely on the model’s accuracy. Engineering teams can identify failures long before production begins.

3. Manufacturing Preparation

3D models drive:

CNC programming,

toolpath generation,

mold design,

sheet-metal unfolding,

and additive manufacturing workflows.

This reduces human error and ensures every part can be produced within tolerance.

4. Quality Assurance & Digital Twin Integration

After manufacturing, 3D models are used to compare produced components against nominal geometry, enabling high-accuracy QA/QC.

Digital twins help maintain, service, and optimize products throughout their lifecycle.

Key 3D Modeling Technologies Transforming 2026 Workflows

Modern product teams rely on a toolbox of advanced modeling technologies:

Parametric CAD — geometry controlled by constraints and engineering logic

NURBS modeling — smooth, complex surfaces for automotive and aerospace

Scan-to-CAD modeling — converting real-world objects into engineering-grade models

Simulation-based modeling — testing performance before prototyping

Generative design — AI-generated shapes optimized for strength and weight

AI-assisted modeling tools — predictive geometry correction and automated detailing

These technologies allow companies to reduce development time, eliminate ambiguity, and build smarter, lighter, and more efficient products.

Industries That Benefit the Most

3D modeling is now essential in:

Consumer electronics — compact multiprocessor devices and enclosures

Automotive & EV — aerodynamics, battery housings, chassis optimization

Aerospace — lightweight structures, composites, CFD-driven geometries

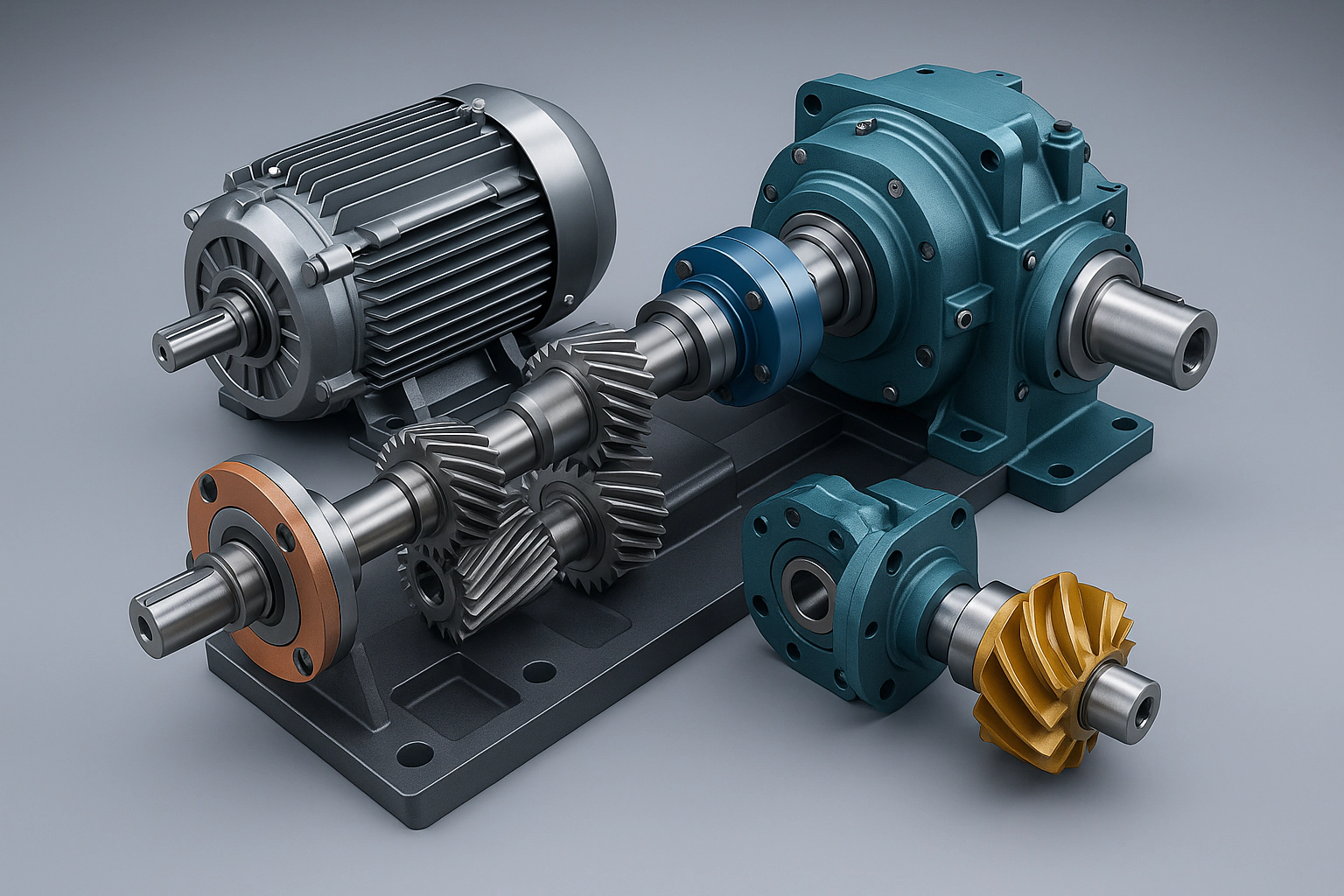

Robotics — kinematic assemblies, end-effectors, precision housings

Medical devices — ergonomic forms, anatomical models, regulatory compliance

Manufacturing & tooling — jigs, fixtures, molds, custom tooling

Industrial R&D — concept development, experiments, prototyping

Each of these sectors requires precise digital geometry as the foundation of both design and production.

Outsourcing vs. In-House: What Companies Choose in 2026

While many companies maintain internal engineering teams, the increasing complexity of products and the shortage of highly skilled CAD specialists have made outsourcing a preferred choice.

Benefits include:

access to specialized expertise,

faster turnaround,

lower overhead costs,

and the ability to scale engineering capability instantly.

Organizations now rely heavily on external modeling partners for simulation-ready CAD, reverse engineering, and production-grade geometry.

Where to Get Professional 3D Modeling Support

Many companies turn to specialized engineering providers offering high-precision CAD modeling, simulation-ready assets, and conversion of scan data into fully parametric models. Firms delivering 3d modeling services USA help accelerate engineering cycles, improve manufacturability, and eliminate costly design errors by providing production-ready digital geometry.

Conclusion

In 2026, 3D modeling is not just a design method — it is the backbone of modern product development. Companies that integrate advanced modeling, simulation, and digital twin workflows gain substantial advantages in cost, speed, and innovation. As manufacturing continues to evolve, organizations that prioritize high-quality digital geometry will remain ahead of competitors and deliver better, smarter products to market—faster and with fewer risks.